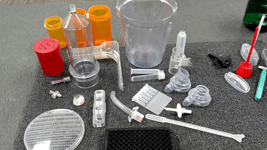

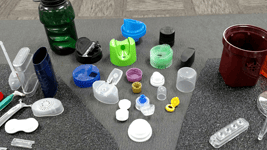

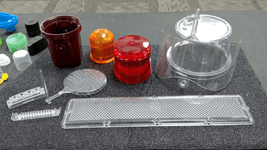

At Precise Polishing, we are a trusted provider of polishing services to plastic injection molding and the tool and die industry. These are customers that require high precision and uncompromising quality. Tooling finishing has a direct and significant impact on its overall performance and ultimately its longevity. Although all tooling at some point will need refurbishment or repair, our goal is to provide polishing and finishing that will maximize tool life and deliver smooth separation and superior finished products.

Even with the best and most innovative tool designs without good finishing and polishing, a tools full potential for efficiency and productivity can never be achieved. Our team of seasoned professionals possess years of experience and are equipped with the tools and facilities to provide world-class polishing and finishing. This allows us to provide flawlessly blended welds and the best buffing available by any provider. Our team consists of more than just operators and technicians, we are craftsmen and work to a code of quality that is unmatched in the industry.

Our team specializes in the use of diamond, paper, and stone mediums, buffing with wheels or loose abrasives. These are manual processes, ideal for castings, forgings, dies, molds, and plates with complex designs and intricate geometries. Regardless of SPI finish or tool material, customers that entrust their tooling to us are guaranteed the best quality and turnover times available. From a single prototype to long term blanket orders that span many months, we provide the same level of customer service and attention to detail. To learn more about this service, or all of our tooling services, contact us directly.